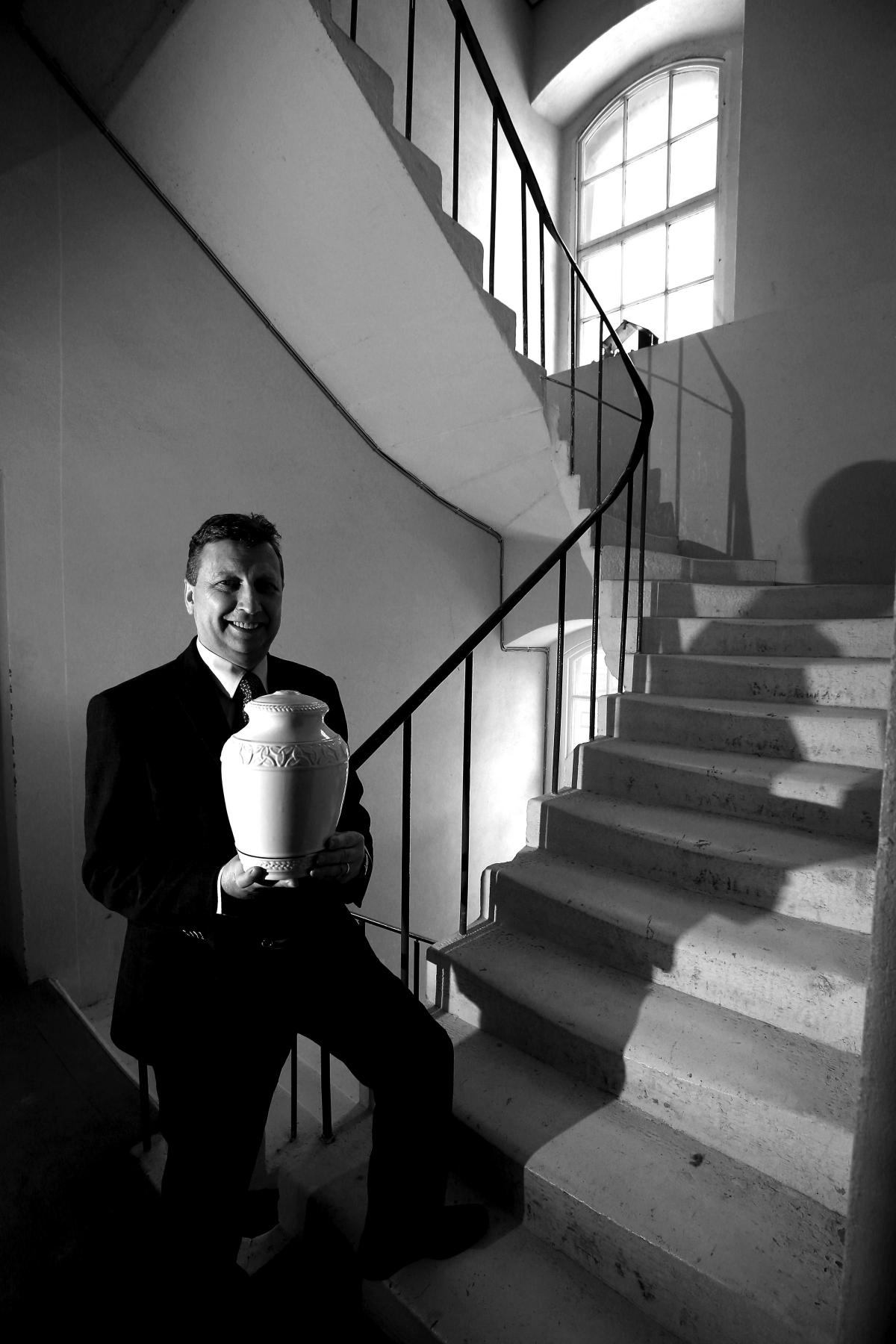

A first for the Fermanagh-based porcelain company, Belleek Pottery have been commissioned by an American client to create an "Irish styled" funeral urn.

Fergus Cleary, Head of Design at Belleek Pottery explained: "We got a request from a customer in the United States who has a funeral business where he provides urns and other goods to different funeral parlours."

He continued: "He came up with this idea of doing an Irish styled funeral urn, presumably hoping to appeal to people of Irish American descent, so he approached us."

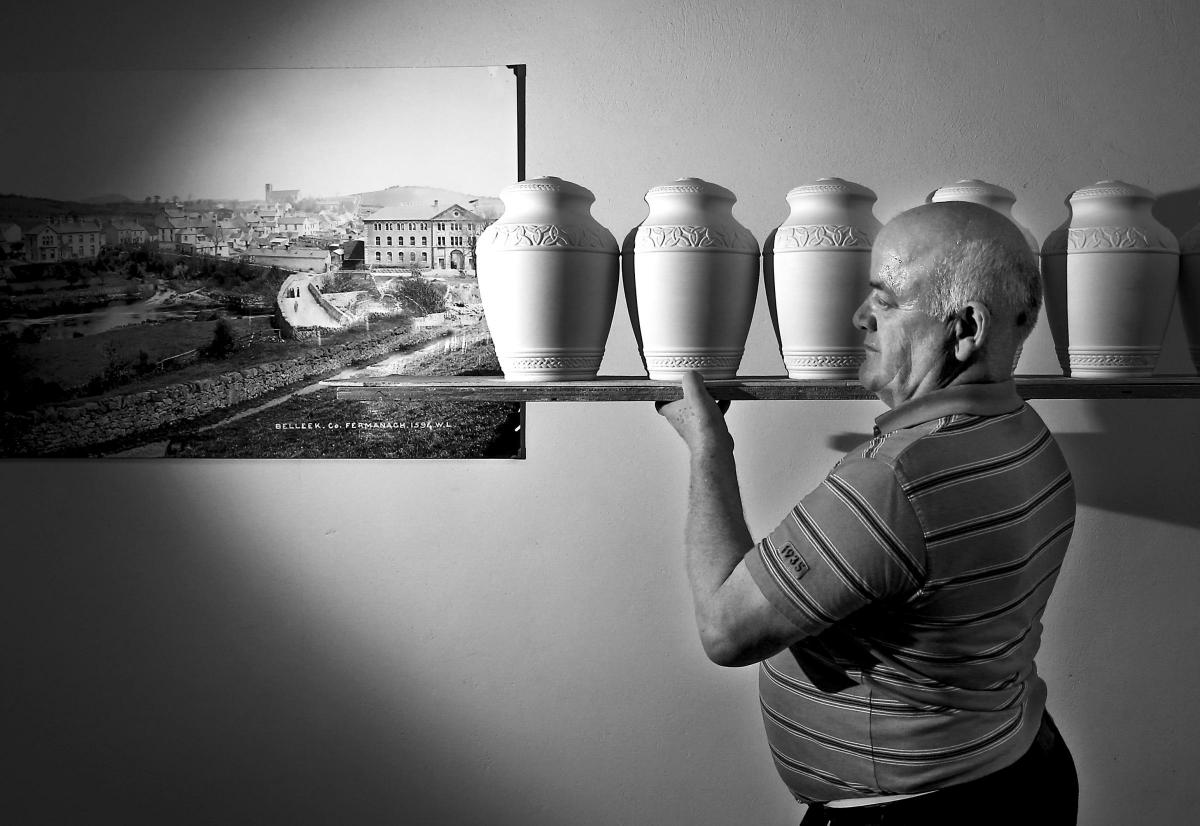

Over the last six months, various teams at Belleek Pottery have been working on the funeral urn from initial designs to final product and at the end of this week, the first batch will be dispatched to the United States.

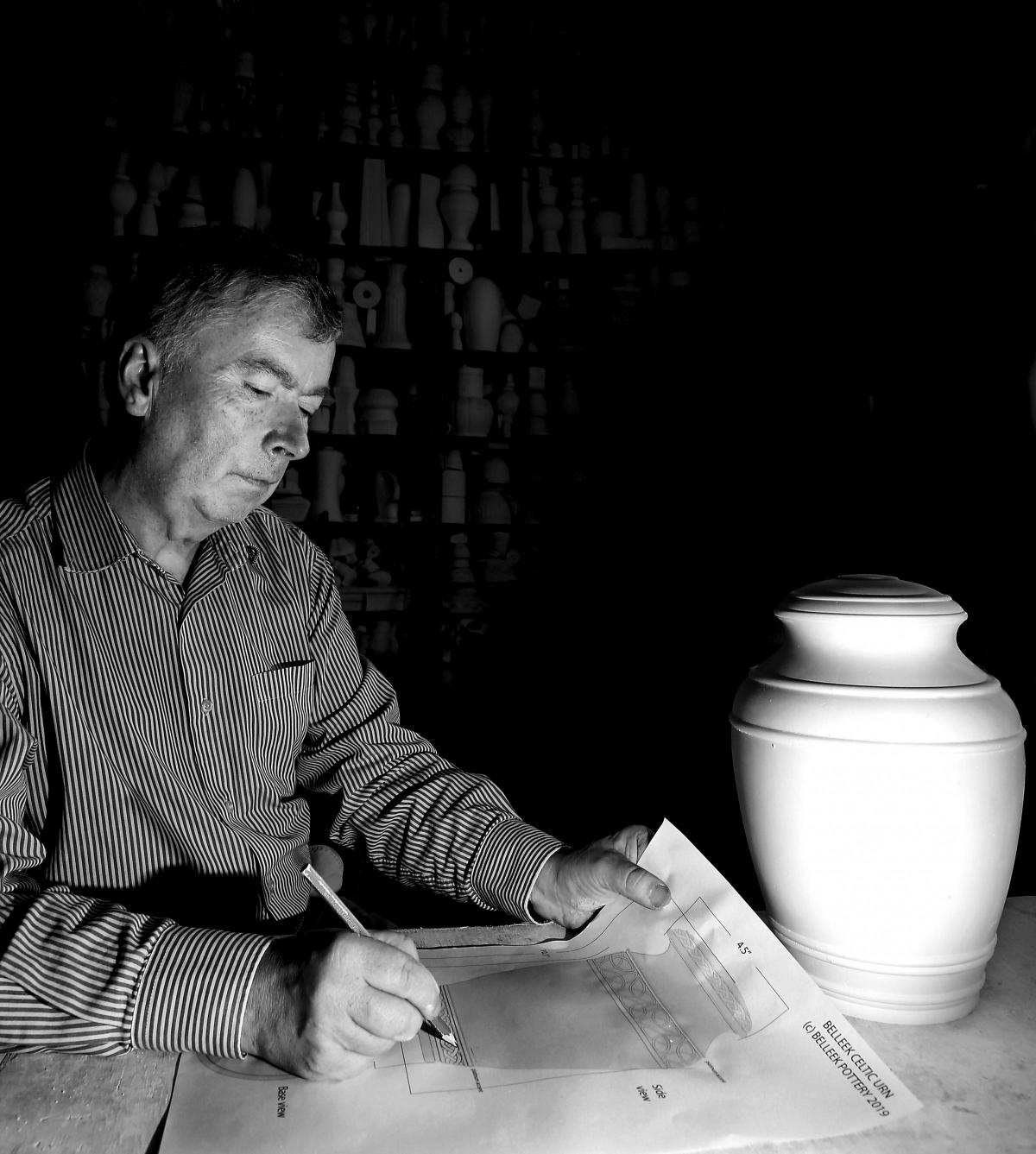

"We worked on some different ideas and drawings and we finally came to one that he liked. We started producing it then, by modelling up the piece and doing some samples, then he approved the samples," said Fergus. He added: "The order has just come in in the last month and the first batch of them are to be dispatched this Friday."

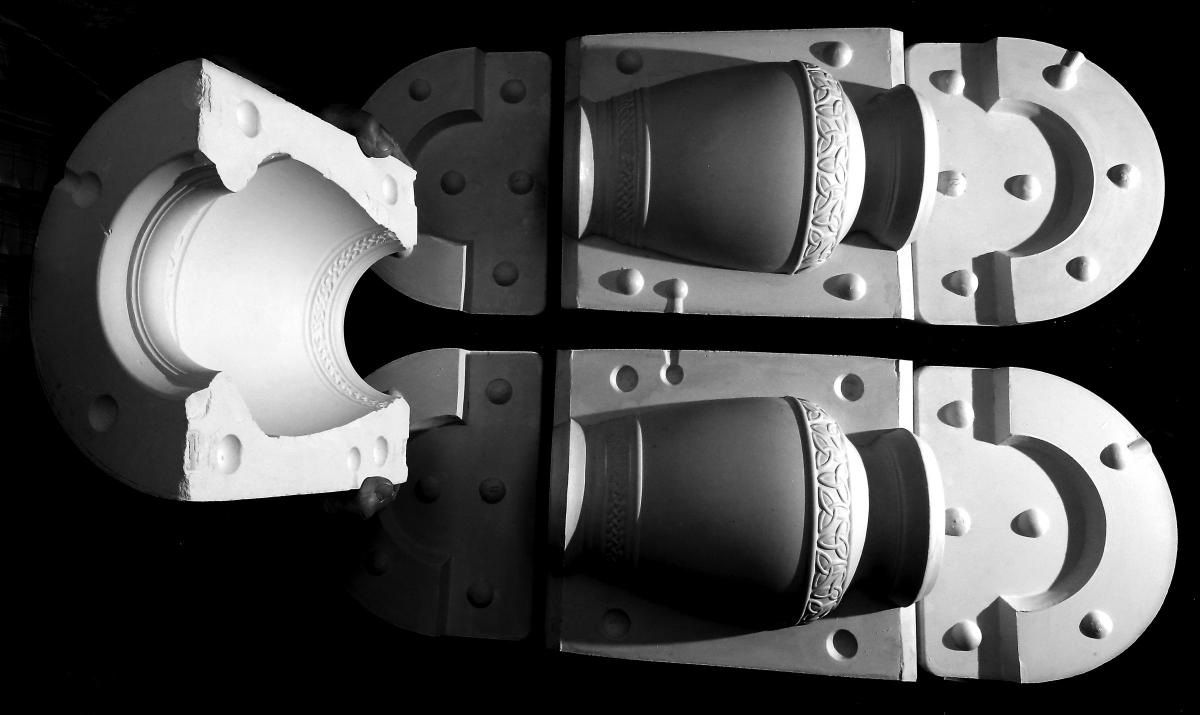

Explaining the process from start to finish, Fergus said: "It starts off with drawing and from the drawing you then make a model. From the model you make a mould and once the mould is made, it’s cast in liquid clay which we call a slip."

He continued: "Once it’s dried, it then goes through the first firing which we call the biscuit firing. It goes to a temperature of 1,200 degrees centigrade for that firing."

Fergus explained that following the first firing, the urn is then checked for any imperfections before it is coated in glaze. It is then fired to 1,000 degrees centigrade and checked again for any flaws.

After the second firing, the urn is given a stamp and decorated.

For the decoration, the client chose celtic symbols designed by the Belleek Pottery design team. The celtic symbols are complimented by two simple platinum lines, a design feature requested by the client.

"There’s a shamrock then painted on the base of it as well," added Fergus.

Once the urn has been decorated it goes for a final firing at 750 degrees centigrade. It is then checked again for any flaws before it's packed and ready for dispatch.

"The production stage from start to finish takes about a week," said Fergus.

Fergus noted that when creating the urns, many of the stages of production are completed by hand.

"It’s all painted by hand and they are cast by hand as well," he said.

"It has to be put in the kilns by hand and then it has to be glazed by hand, it’s checked by hand as well for any flaws or imperfections. It takes about 16 pairs of hands to process every piece of Belleek, from start to finish," continued Fergus.

"It’s certainly a hands-on process," he added.

Now complete, the first batch, which consists of approximately 250 urns, will be dispatched on Friday.

"Most of them are travelling to the United States and some of them are travelling to England. This man has a customer there as well who is taking some of them," explained Fergus.

"Potentially it could go worldwide as he has contacts all over the world in different countries," he said.

Fergus concluded: "It’s probably one of our most unusual projects to date. It’s always interesting to do something new."

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here